Wellington College, UK

Wellington College is one of the world's top coeducational day and boarding schools founded in 1859, just outside London, combining innovation with 150 years of history.

The project is set within the Wellington Estate and comprises two new buildings within a woodland setting. The larger boarding house is up to 4 storeys and cellular in composition whereas the day house is 3 storeys with a roof terrace and a large entrance atrium with exposed glulam portal frames. Both buildings include feature CLT stairs with exposed CLT but the majority of the buildings is lined for acoustics reasons.

In 2021, Define Engineers were appointed at stage 3 to provide specialist mass timber input for the engineering of the CLT superstructure of the new Woodland Quad buildings of Wellington College. DE’s specialist mass timber and DfMA were key to provide early cost assurance and carbon benchmarking in the design iterations required to adapt the scheme to mass timber whilst maximising on change of grid opportunities and heavy brick overhangs.

Architect – Mica Architects, London

Structural Engineer Superstructure – Define Engineers

Structural Engineer Substructure – Glanville Consultants

Define’s scope : Client sie structural engineering, Novation to timber contractor as structural engineer, Permanent and temporary structural analysis in RFEM Dlubal, Construction sequence, Timber products selection & treatment, Full BIM to LOD 300, Complete performance specification writing, Tender process preparation

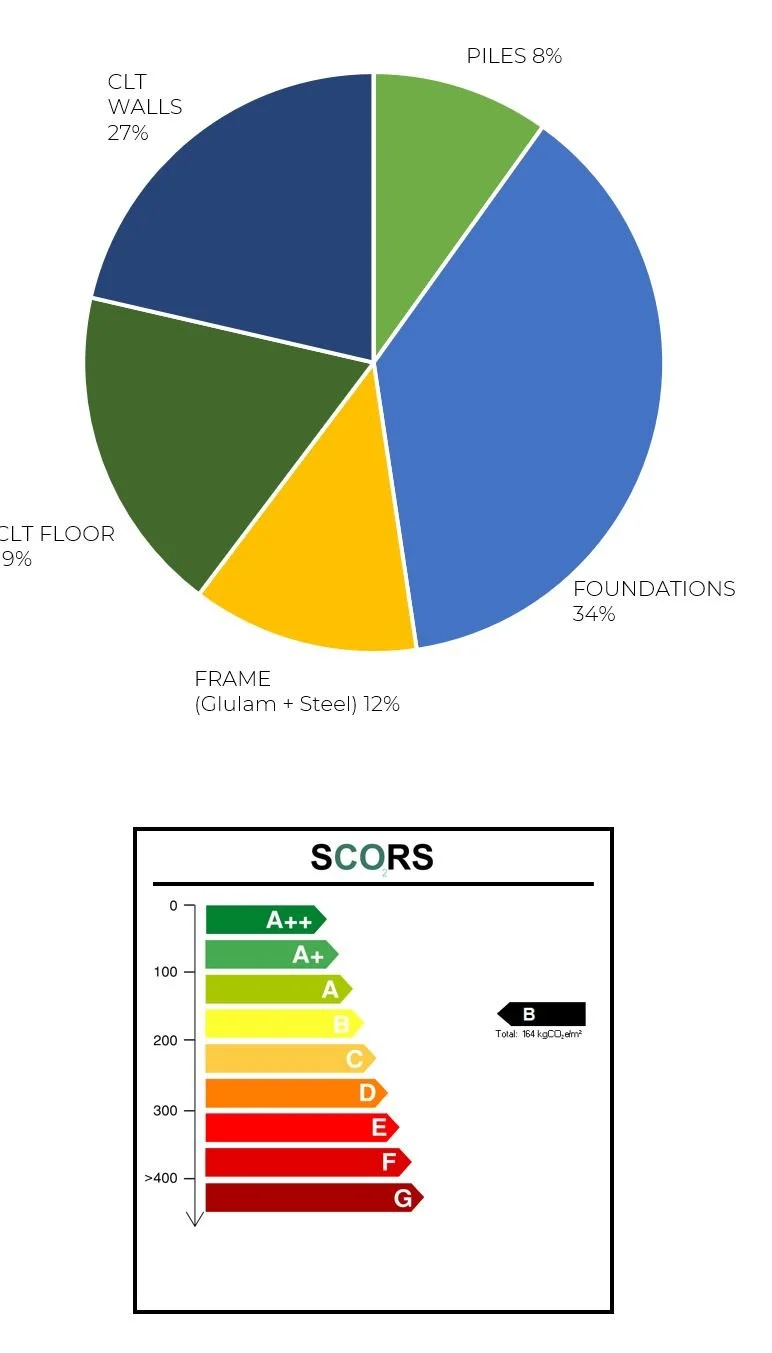

RIBA 2030 challenge brief

Although we weren’t involved before stage 3, close collaboration with the design team have allowed us to bring the structural embodied carbon to within 10% of the RIBA 2030 targets. This was achieved by means of highlevel optioneering and communicating impact on carbon footprint to allow for holistic decisions to be made to minimise overall weight. The final benchmark is seen as indicative and subject to final EPDs but the process allowed us to inform the design development.

CLT offers a multitude of benefits in regard to the performance and sustainability of the environment. As it is available readily manufactured from sustainably managed forests as well as its long-term storage of the carbon absorbed by the sustainably grown trees, the production of CLT results in substantially fewer greenhouse gas emissions than many non-wood materials. Due to their pre-engineered nature panels are manufactured to exact measurements and requirements which results is less wastage and a simplified building process.

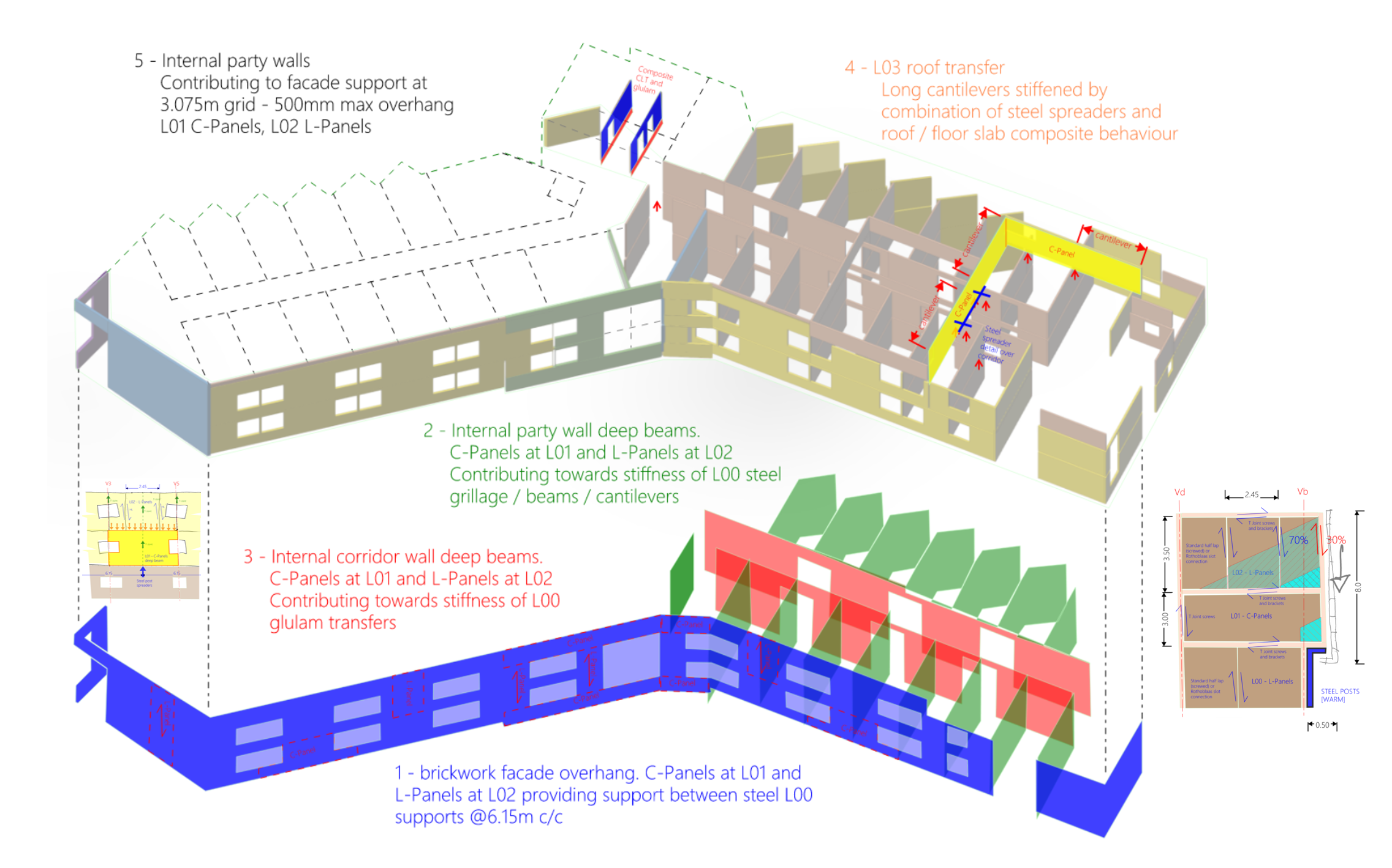

Generally, repetitive floor layouts, moderate spans and position of structural walls create a simple scheme in terms of gravity load paths through the building and the foundations. Where transfers could not be avoided, we have tried to maximise on use of deep beam action from CLT walls. However, the requirement for heavy brick facade required an added 15% in embodied carbon in the steel support structure.

Solid timber building structures are typically 50%-75% lighter than traditional concrete structures due to the high strength-to-weight ratio. This results in a 40% reduction in overall building weight and a similar reduction in the cost and carbon impact of the foundations.

The impact on the scheme by the overhanging brickwork façade has been quantified as approximately 15% (i.e. a lightweight timber clad façade would have had 15% less embodied carbon, this is a lower bound figure as it includes structure and superstructure only, not carbon in the facade).

Sequestration and Substitution are not accounted in the above estimates, however the use of CLT brings further advantages over traditional steel / concrete:

-Carbon storage (1m3 of CLT equates to approx. 0.9t of C02 stored by tree growth)

-Energy substitution (1m3 of CLT avoids approx 1.1t C02 emissions from traditional)

Based on the above, the estimated carbon substitution + sequestration is approx. 5 times the calculated structural carbon count (vs equivalent traditional build).

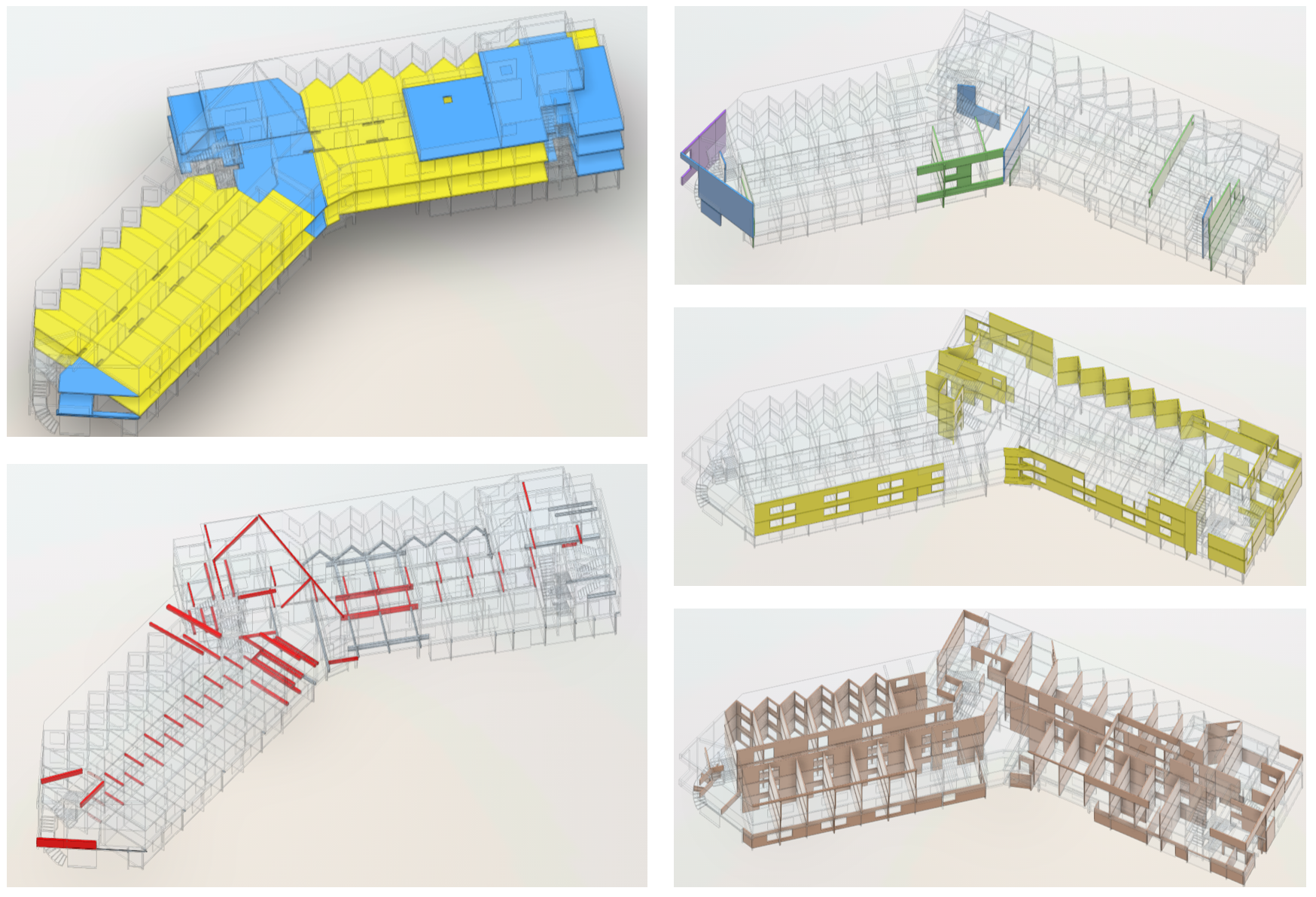

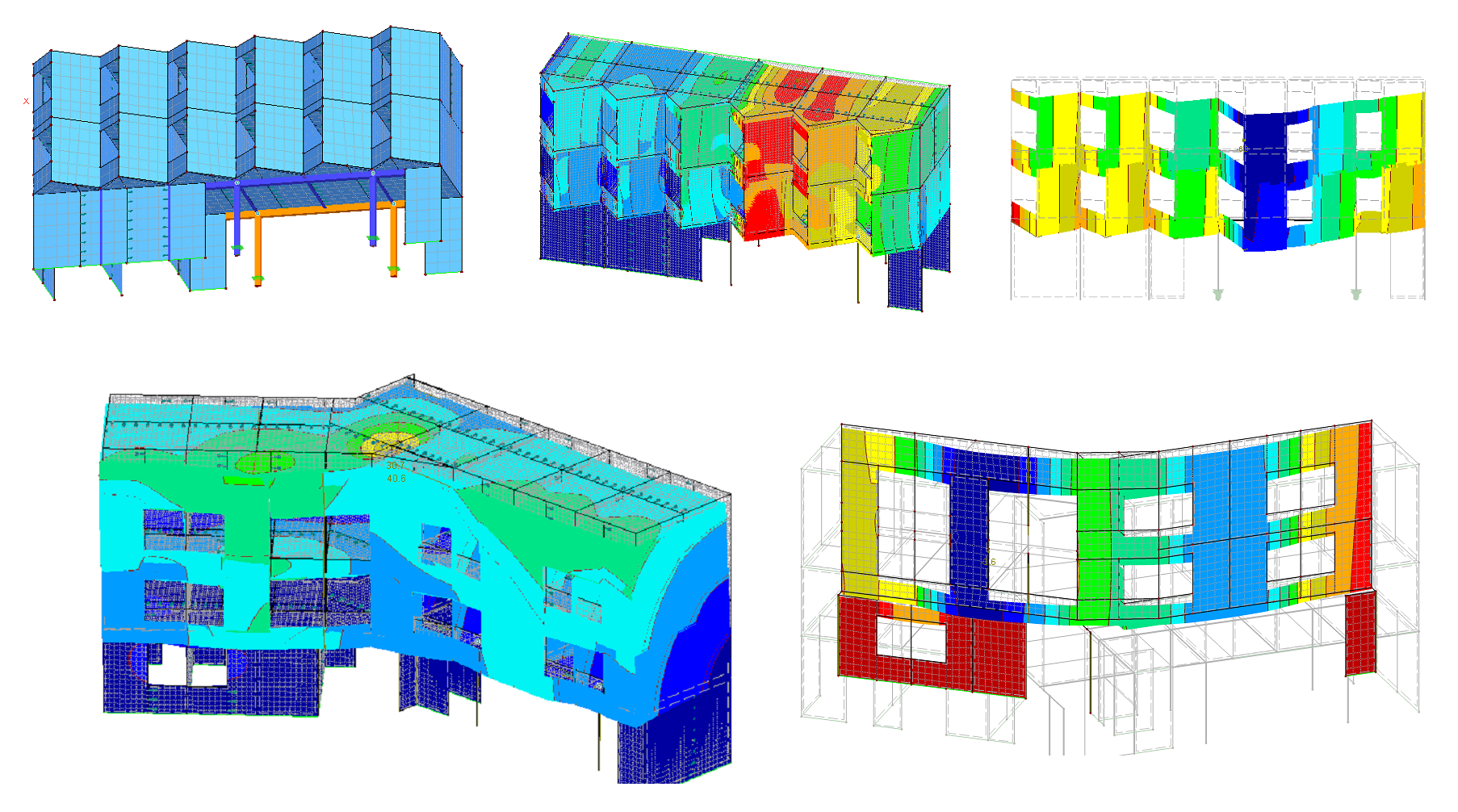

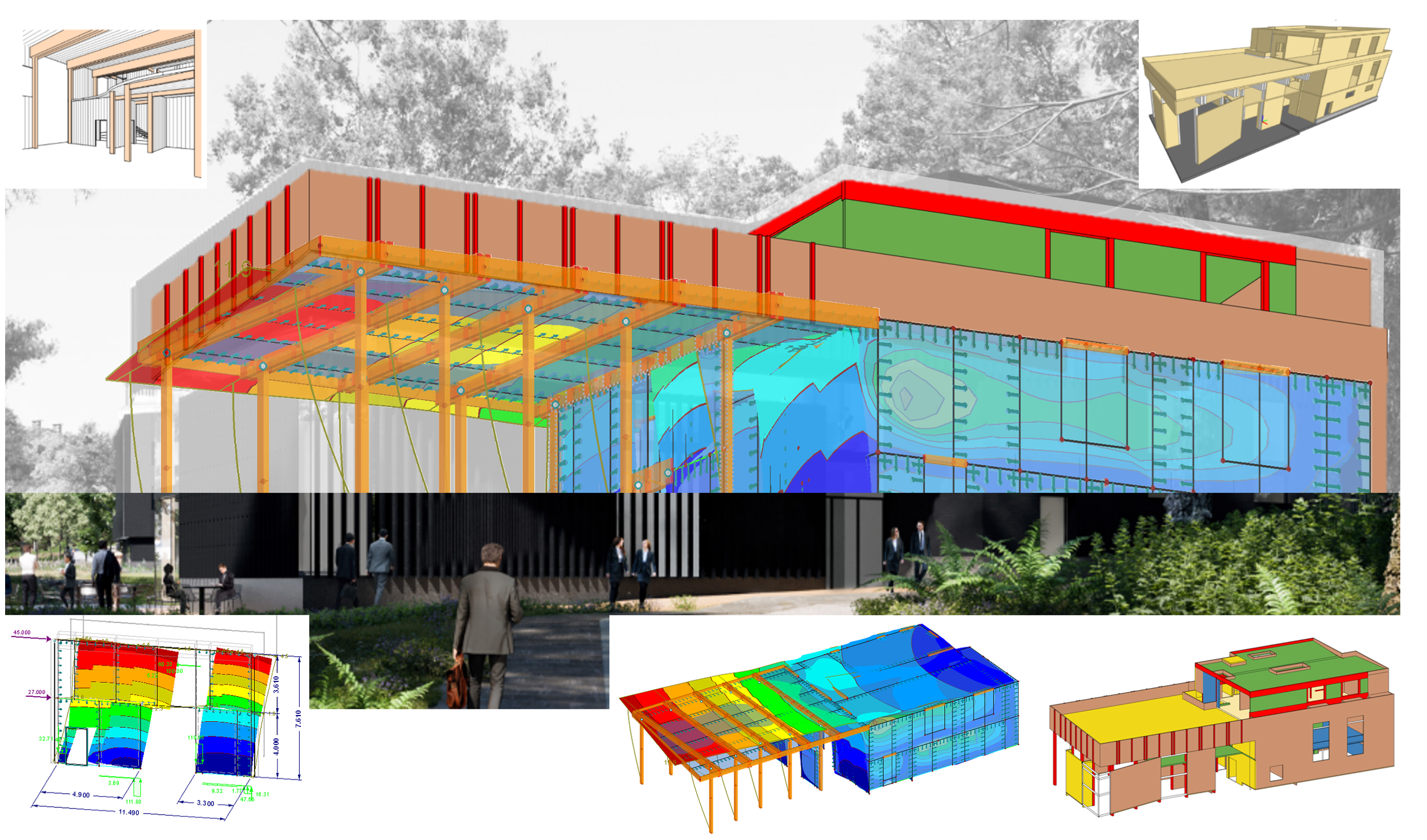

Night Building modelling - stage 3 modelling - high level DfMA happening in background

Night Building modelling for overhang deflections from brick loading, space for further stage 4 refinement of steelwork by maximising on CLT contribution to stiffness

High level sketches to communicate structural strategy

Day Building modelling - stage 3 modelling - high level DfMA in the background

Day Building analysis - Eccentric stability and open atrium portal frame

Day and Night buildings modelled for high level stage 3 costing